Processing Flax

After the flax has been retted and dried, you then have to use a brake, scutching knife, and hackle to turn the dried plant into flax fibres

Rippler

![How to ripple]()

![Seed balls]()

![Seed balls]()

![Opened Seeds]()

Rippling is the first step to processing flax into fibre after the flax has been retted.

Rippling is when you remove the seeds or capsules from the stalk of the flax plant, using a comblike object called a rippler. By pulling the bundles of flax through the rippler, the stalks go through it but the seed balls pop off, making it an easy way to harvest all the flax seeds!

You can then save the seeds for a future plot of flax to be grown or feed the seeds to farm animals!

Brake (hand or mechanical)

![Examples of a brake]()

![Examples of a brake]()

![Examples of a brake]()

![Flax entering a mechanical brake]()

The second step in processing flax.

Breaking forcefully cracks open the stalk of the plant, seperating the woody shive, or boon, from the long fibres within. It is carried out by hand using a wooden tool called a flax brake (or break), or in flax mills by passing the retted plants along interlocking fluted rollers.

Breaking apart these fibres within the plant makes it more malleable, where you can then move onto the scutching process

Rippler

![How to ripple]()

![Seed balls]()

![Seed balls]()

![Opened Seeds]()

Rippling is the first step to processing flax into fibre after the flax has been retted.

Rippling is when you remove the seeds or capsules from the stalk of the flax plant, using a comblike object called a rippler. By pulling the bundles of flax through the rippler, the stalks go through it but the seed balls pop off, making it an easy way to harvest all the flax seeds!

You can then save the seeds for a future plot of flax to be grown or feed the seeds to farm animals!

Rippling is the first step to processing flax into fibre after the flax has been retted.

Rippling is when you remove the seeds or capsules from the stalk of the flax plant, using a comblike object called a rippler. By pulling the bundles of flax through the rippler, the stalks go through it but the seed balls pop off, making it an easy way to harvest all the flax seeds!

You can then save the seeds for a future plot of flax to be grown or feed the seeds to farm animals!

Brake (hand or mechanical)

![Examples of a brake]()

![Examples of a brake]()

![Examples of a brake]()

![Flax entering a mechanical brake]()

The second step in processing flax.

Breaking forcefully cracks open the stalk of the plant, seperating the woody shive, or boon, from the long fibres within. It is carried out by hand using a wooden tool called a flax brake (or break), or in flax mills by passing the retted plants along interlocking fluted rollers.

Breaking apart these fibres within the plant makes it more malleable, where you can then move onto the scutching process

The second step in processing flax.

Breaking forcefully cracks open the stalk of the plant, seperating the woody shive, or boon, from the long fibres within. It is carried out by hand using a wooden tool called a flax brake (or break), or in flax mills by passing the retted plants along interlocking fluted rollers.

Breaking apart these fibres within the plant makes it more malleable, where you can then move onto the scutching process

Scutching

![]()

![]()

![]()

After breaking the flax, the next step is to scutch.

Scutching is to remove remaining woody bits, or shives, from flax fibres to clean the strands. Scutching is carried out by scraping or beating the flax using a large blunt wooden knife, or in flax mills by passing broken flax through large drums with rotating blades.

Hand scutching can be done in the air, on your leg, or against a wooden board.

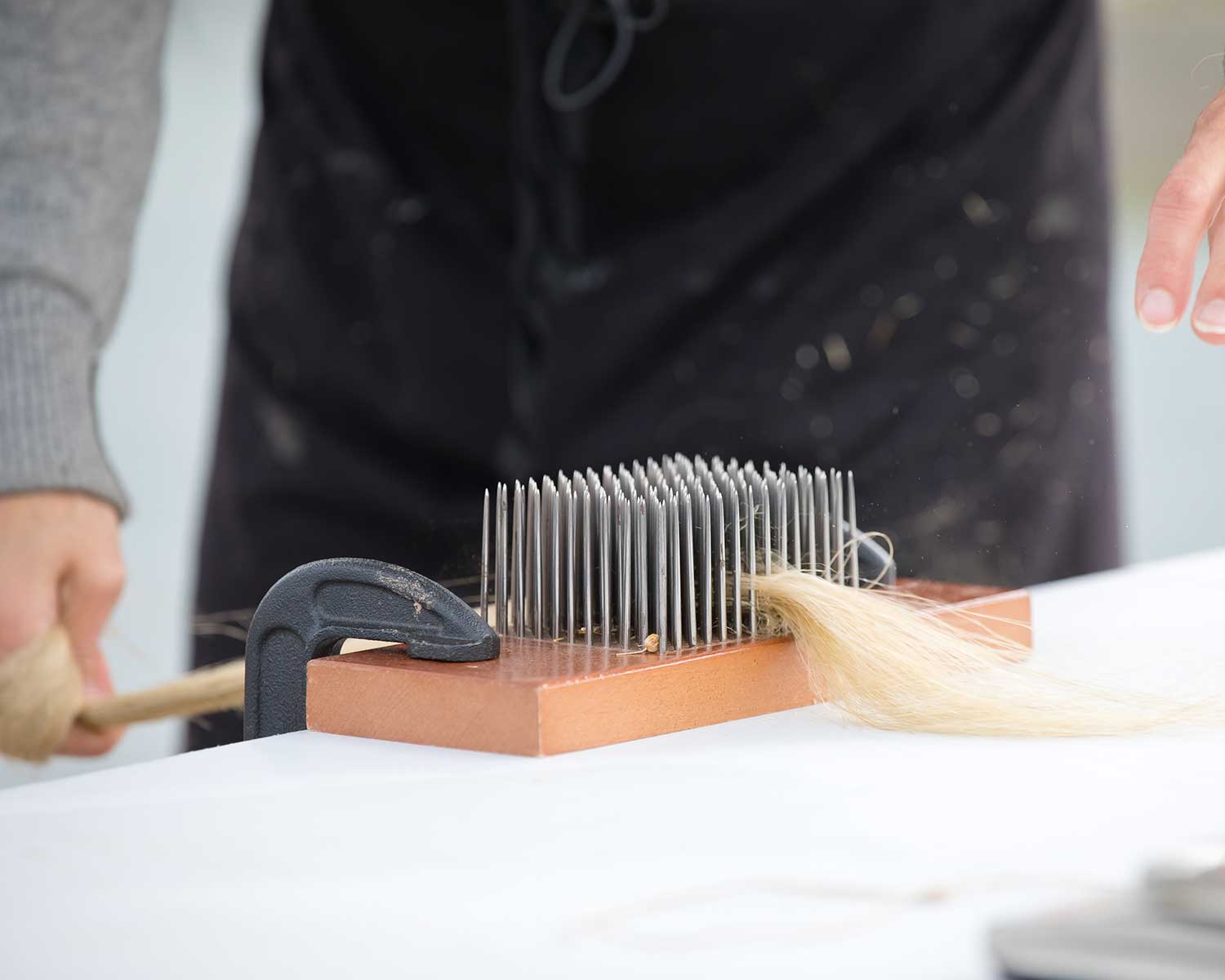

Hackling

Hackling involves pulling flax fibre through a series of finer and finer combs called hackles, to further clean and seperate the fibres. It is the final step of fibre extraction; the flax is ready for spinning once completed.

Hackles are built similarly to a rippler and are clamped to a flat surface.

Flax fibres