Planting Flax

Prepping the soil

Sowing the seeds

![Using a seeder]()

![Hand broadcasting]()

![Example of hand broadcasting]()

Raking and compressing the soil

Weeding

The act of weeding

Weeding is crucial to do in the flax growth process to identify potential problems in the soil or the seed being used. Typically, weeding should occur prior to the crop reaching 6 inches in height. Weeds in the seedling stage are easiest to control and there is a decreased risk to injury of the crop at the early growing stages.

Documenting

When going through the plot of flax, you need to make note of any weeds popping up. As well as any flax plants that are growing abnormally. Weeds and flax issues can give you an insight into the soil health and can point you in the right direction when trying to create the healthiest batch of flax possible.

If a plant is growing abnormally, it could be lacking nutrients. Following a planting log document, and our Growers Guide with helpful illustrations, can help you identify potential problems.

Weeds

Plant Growth Issues

Harvesting

Harvesting flax is typically done 90-125 days after seeding. The flax seed bolls will be shades of brown and yellow, and the leaves will be drooping downwards. Harvesting is part of what ensures the flax fibres quality after its been fully processed.

![Deanery Project]()

![]()

![]()

![]()

![Prospect Farm]()

![]()

![]()

![]()

![North Grove]()

![]()

![]()

![]()

![Coady & Thompkins]()

![]()

![]()

![]()

Retting

![Dew Retting]()

![Tank Retting]()

![Tank Retting]()

![]()

Dew retting is the oldest and still most common form of retting. After the flax has been pulled, it is spread evenly in the field, and over the course of the next 3-7 weeks, depending on climatic conditions, natural decomposing bacteria work to dissolve the pectin material around the plant stalks.

At Flaxmobile we have also used tank, and wet retting depending on the location and flax condition.

Tank retting, by contrast, employs vats usually made of concrete, requires about four to six days, and is feasible in any season. In the first six to eight hours, called the leaching period, much of the dirt and colouring matter is removed by the water, which is usually changed to assure clean fibre.

Stooking

![In a barn]()

![Tied bundles]()

![In a field]()

Stooking is the process of bundling and tying flax into sheaves so it can dry evenly and be stored for processing into linen. The uprooted plants are gathered into bundles. The best flax will dry to a lighter color than the lower quality plants.

Retting

![Dew Retting]()

![Tank Retting]()

![Tank Retting]()

![]()

Dew retting is the oldest and still most common form of retting. After the flax has been pulled, it is spread evenly in the field, and over the course of the next 3-7 weeks, depending on climatic conditions, natural decomposing bacteria work to dissolve the pectin material around the plant stalks.

At Flaxmobile we have also used tank, and wet retting depending on the location and flax condition.

Tank retting, by contrast, employs vats usually made of concrete, requires about four to six days, and is feasible in any season. In the first six to eight hours, called the leaching period, much of the dirt and colouring matter is removed by the water, which is usually changed to assure clean fibre.

Stooking

![In a barn]()

![Tied bundles]()

![In a field]()

Stooking is the process of bundling and tying flax into sheaves so it can dry evenly and be stored for processing into linen. The uprooted plants are gathered into bundles. The best flax will dry to a lighter color than the lower quality plants.

Stooking is the process of bundling and tying flax into sheaves so it can dry evenly and be stored for processing into linen. The uprooted plants are gathered into bundles. The best flax will dry to a lighter color than the lower quality plants.

Processing Flax

After the flax has been retted and dried, you then have to use a brake, scutching knife, and hackle to turn the dried plant into flax fibres

Rippler

![How to ripple]()

![Seed balls]()

![Seed balls]()

![Opened Seeds]()

Rippling is the first step to processing flax into fibre after the flax has been retted.

Rippling is when you remove the seeds or capsules from the stalk of the flax plant, using a comblike object called a rippler. By pulling the bundles of flax through the rippler, the stalks go through it but the seed balls pop off, making it an easy way to harvest all the flax seeds!

You can then save the seeds for a future plot of flax to be grown or feed the seeds to farm animals!

Brake (hand or mechanical)

![Examples of a brake]()

![Examples of a brake]()

![Examples of a brake]()

![Flax entering a mechanical brake]()

The second step in processing flax.

Breaking forcefully cracks open the stalk of the plant, seperating the woody shive, or boon, from the long fibres within. It is carried out by hand using a wooden tool called a flax brake (or break), or in flax mills by passing the retted plants along interlocking fluted rollers.

Breaking apart these fibres within the plant makes it more malleable, where you can then move onto the scutching process

Rippler

![How to ripple]()

![Seed balls]()

![Seed balls]()

![Opened Seeds]()

Rippling is the first step to processing flax into fibre after the flax has been retted.

Rippling is when you remove the seeds or capsules from the stalk of the flax plant, using a comblike object called a rippler. By pulling the bundles of flax through the rippler, the stalks go through it but the seed balls pop off, making it an easy way to harvest all the flax seeds!

You can then save the seeds for a future plot of flax to be grown or feed the seeds to farm animals!

Rippling is the first step to processing flax into fibre after the flax has been retted.

Rippling is when you remove the seeds or capsules from the stalk of the flax plant, using a comblike object called a rippler. By pulling the bundles of flax through the rippler, the stalks go through it but the seed balls pop off, making it an easy way to harvest all the flax seeds!

You can then save the seeds for a future plot of flax to be grown or feed the seeds to farm animals!

Brake (hand or mechanical)

![Examples of a brake]()

![Examples of a brake]()

![Examples of a brake]()

![Flax entering a mechanical brake]()

The second step in processing flax.

Breaking forcefully cracks open the stalk of the plant, seperating the woody shive, or boon, from the long fibres within. It is carried out by hand using a wooden tool called a flax brake (or break), or in flax mills by passing the retted plants along interlocking fluted rollers.

Breaking apart these fibres within the plant makes it more malleable, where you can then move onto the scutching process

The second step in processing flax.

Breaking forcefully cracks open the stalk of the plant, seperating the woody shive, or boon, from the long fibres within. It is carried out by hand using a wooden tool called a flax brake (or break), or in flax mills by passing the retted plants along interlocking fluted rollers.

Breaking apart these fibres within the plant makes it more malleable, where you can then move onto the scutching process

Scutching

![]()

![]()

![]()

After breaking the flax, the next step is to scutch.

Scutching is to remove remaining woody bits, or shives, from flax fibres to clean the strands. Scutching is carried out by scraping or beating the flax using a large blunt wooden knife, or in flax mills by passing broken flax through large drums with rotating blades.

Hand scutching can be done in the air, on your leg, or against a wooden board.

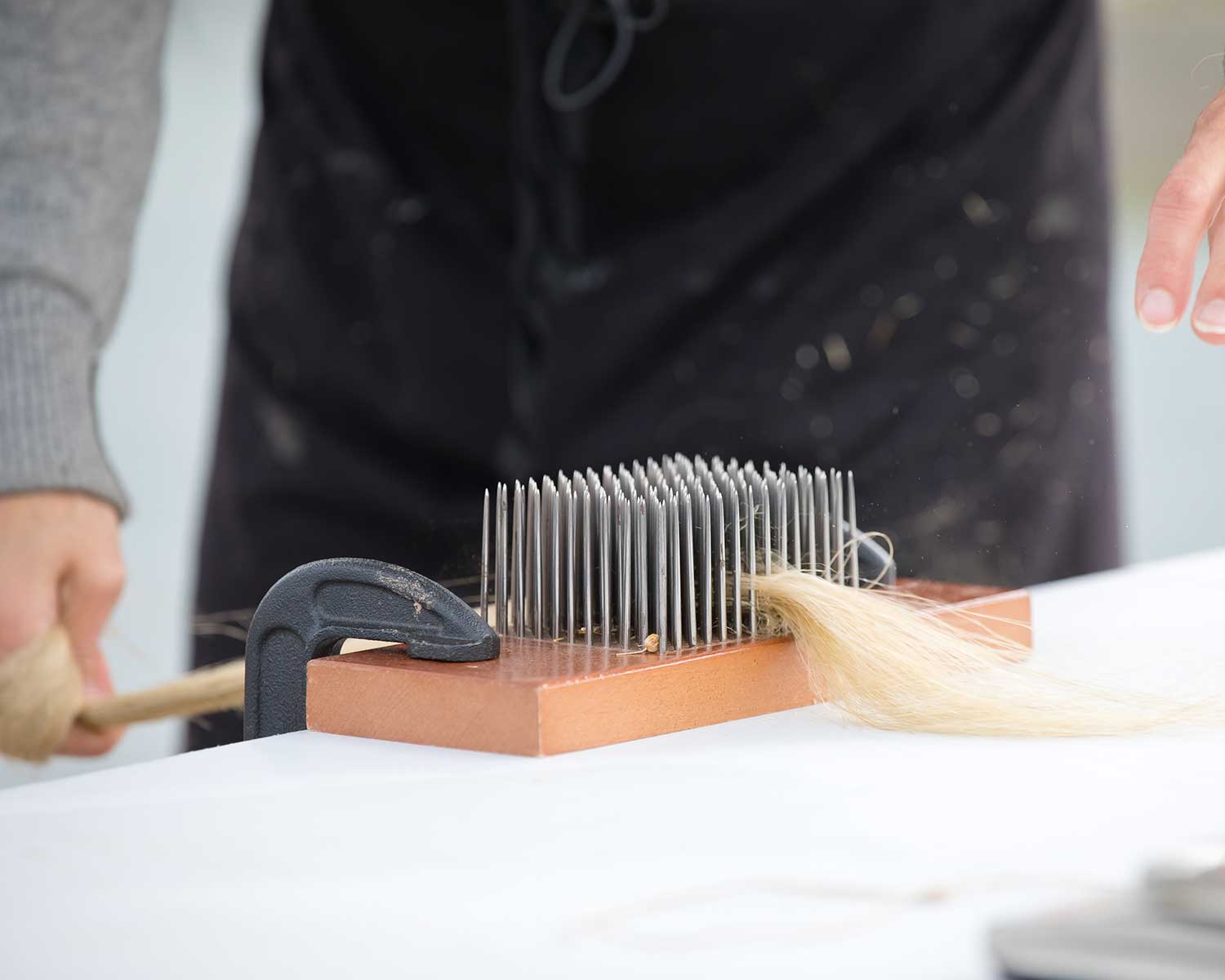

Hackling

Hackling involves pulling flax fibre through a series of finer and finer combs called hackles, to further clean and seperate the fibres. It is the final step of fibre extraction; the flax is ready for spinning once completed.

Hackles are built similarly to a rippler and are clamped to a flat surface.

Flax fibres